You may have heard of extruded aluminum before, but not everyone knows what it is and what it is.

However, it is important to know this construction material, as it is found in almost half of the products made with aluminum that we use in our day to day, without being aware of it and its importance.

In fact, many of the automatic aluminum sliding doors that are worked on at Portalum are produced with this material. There are also windows that you can find in houses and common buildings are made with aluminum molded through the extrusion process.

If you want to know more about aluminum extrusion, what it is, what it consists of, how it is made, what its main benefits are and what type of doors you can find it in, keep reading, since, in this post, we are going to explain all this information in detail so that you have no doubts about it.

Aluminium extrusion process What is it for?

First of all, it is important to know what this aluminium extrusion process consists of, which gives the final product its name: extruded or extruded aluminium.

In reality, aluminum extrusions are very simple to understand, as it is not a very complex process, and it allows the metal to be molded using a relatively low amount of resources and with little effort.

In a nutshell, to achieve an extruded aluminium profile, a shapeless aluminium bar, called a billet, is first heated and pressurised into a prefabricated shape, called a matrix, thus giving the desired shape to the billet.

This process consists of creating an aluminum part with the desired shape in a simple, fast and effective way, and being able to manufacture a large number of very resistant parts or bars in a very short time.

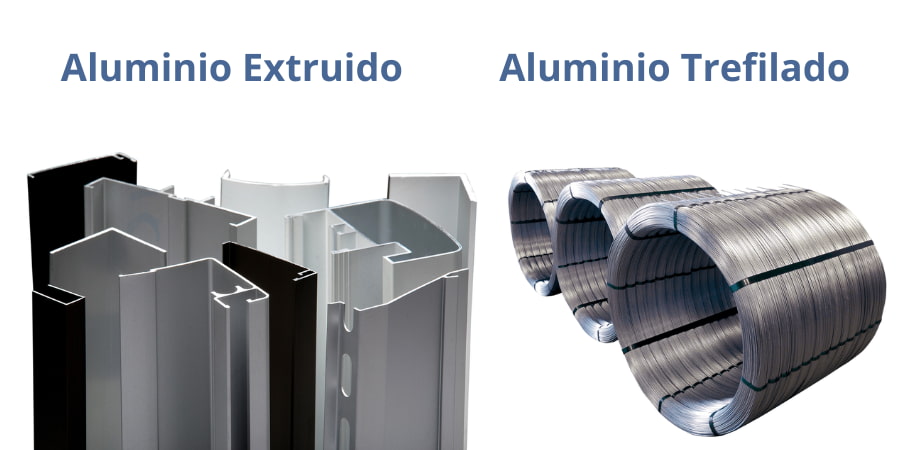

Differences Between Extruded Aluminum and Drawn Aluminum

Manufacturing Process

Extruded aluminum is obtained by forcing the material to pass inside a die at high temperatures, which allows various shapes and profiles to be obtained. Instead, drawn aluminum is produced by stretching the material through a series of holes, gradually reducing its diameter.

In the extrusion process, the material is heated to its plasticity point and pushed through a die using a press. On the other hand, the drawing process involves stretching the material through a swath or die, by applying a tensile force.

Sectors of application

Extruded aluminum is primarily used in the construction industry due to its strength, durability, and ability to obtain different shapes, such as tubes, channels, and beams. It is used in the manufacture of aluminum rolling doors, exterior sliding doors for garages, windows, etc.

Instead, drawn aluminum is primarily used in the transmission and distribution of power, such as electrical conductors, cables, and wires. It is also used in applications where a thinner and stronger material is required, such as in the manufacture of aluminium-coated steel cables. Therefore, we summarize that:

Extruded aluminum:

- It is obtained by the process of extrusion at high temperatures.

- It is used in the construction sector.

- It can take on different shapes and profiles.

Drawn aluminium:

- It is obtained by the process of stretching through a row or die.

- It is used in power transmission and distribution.

- It is used in applications that require thinner and stronger materials.

Aluminum Extrusion: Benefits and Key Features

Strength and durability

Extruded aluminum is known for its high structural strength, which allows it to withstand physical loads and stresses without deforming. This makes it an ideal material for applications in the construction industry, as it can withstand harsh conditions, such as temperature changes, humidity, and corrosion.

In addition to its strength, extruded aluminum stands out for its long-term durability. Its ability to resist oxidation and corrosion ensures a long service life, reducing maintenance and replacement costs.

Variety of shapes and profiles

The aluminium extrusion process makes it possible to obtain a wide variety of shapes and profiles of extruded aluminium.

The extruded aluminum parts obtained are of great resistance, with a perfect shape and with a very low risk of leaving the factory with imperfections or errors.

From bars and tubes to complex and custom profiles, extruded aluminum offers versatility to adapt to different design needs and specific applications.

These profiles can be used in the manufacture of self-locking extruded aluminium safety shutters, façades, among others. Extruded aluminium profiles allow flexibility and create tailor-made solutions, adapted to the technical and aesthetic requirements of each project, such as custom-made aluminium sliding doors.

Fast manufacturing

The aluminum extrusion process manages to manufacture a wide variety of shapes and profiles of similar parts, without any difference or imperfection, in a very short period of time.

In addition, the manufacturing process itself is efficient, since, once a shape is obtained for the die, you only have to pass as many billets or aluminum bars as you want to achieve a large volume of parts without too much effort or costs.

Aluminum extrusion is used today in a large number of countries around the world, as it is very profitable for manufacturers and at the same time allows to offer customers a high quality final product in a short time and with an unbeatable value for money.

In fact, this process of manufacturing aluminium parts is so well known and used, precisely because it offers a series of advantages that cannot be achieved by moulding this metal in any other way.

Manufacture of aluminum doors and rolling doors

To finish with these explanations about extruded aluminum, you only need to know what type of products are usually manufactured and which ones you can easily find on the market.

At Portalum we offer aluminum doors manufactured using this process, thus achieving a result of great resistance. Aluminium roller door slats are manufactured using the extrusion process precisely because it is essential that they are all similar, robust, flawless, and manufactured in large numbers in a short period of time.

In addition, you can also find different types of aluminum doors for garages, roll-up doors for shops and businesses and, in general, any type of medium or large door that is made up of several similar pieces of aluminum and that needs to have an optimal level of resistance, such as those you can find in the Portalum product catalog.